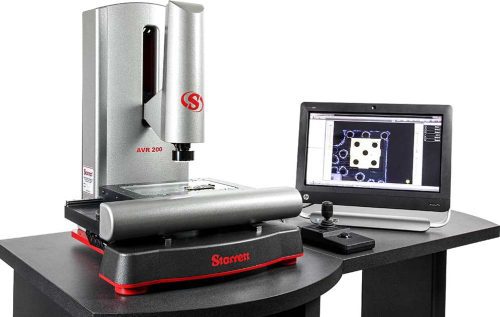

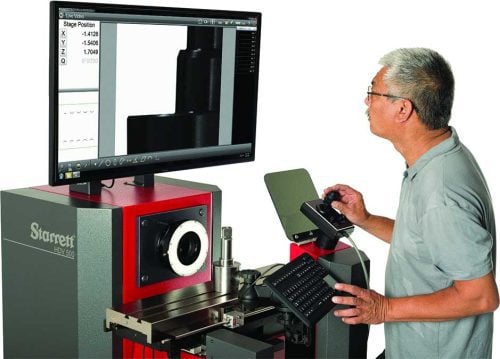

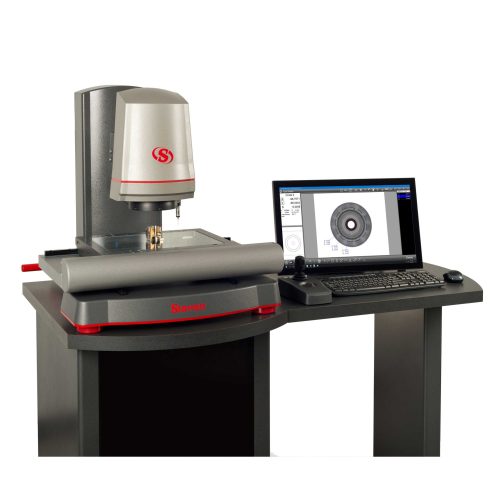

The Starrett AVR Series CNC automatic vision metrology systems are ideal for repetitive measurements and automatic comparison to CAD files. They are available with dedicated 6.5:1 zoom optics or a quick-change bayonet lens mount which accepts a choice of telecentric lenses for micron-level resolution and optical distortion down to 0.001% for accurate field-of-view (FOV) measurements. These can encompass an entire small part up to 2.00" x 1.50" or a feature of a larger part and be seamlessly integrated with stage motion to measure parts with a length up to 8" (AVR200) or 12” (AVR300). Call 1-800-362-0364 or email: sales@ocscal.com for pricing, demo, or more information.

|

Download Sell Sheet for full details and specs |