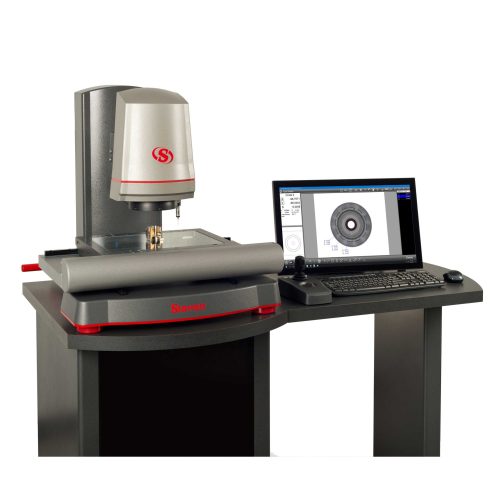

The AVR-FOV 0.14 CNC Automatic Vision Metrology System is ideal for repetitive measurements and automatic comparison to CAD files. Systems are available with a large 2.36" (60mm) FOV-dedicated 0.14X telecentric lense for micron-level resolution and accurate field-of-view (FOV) measurements. The AVR-FOV 0.14 is capable of measuring parts with a length up to 12" (300mm). The operator interface is the MetLogix™ M3 software that displays a live video image of the part plus geometry tools and digital readings. The image of the part can be resized using zoom and measurements can be taken by simply touching a feature on the touch-screen monitor. M3 software capabilities also include 3-axis measurements and 2D geometric constructs (points, lines, angles, rectangles, slots, blobs). Systems are also touch probe compatible. Call 1-800-362-0364 or email: sales@ocscal.com for pricing, demo, or more information.

|

Download Sell Sheet for full details and specs |