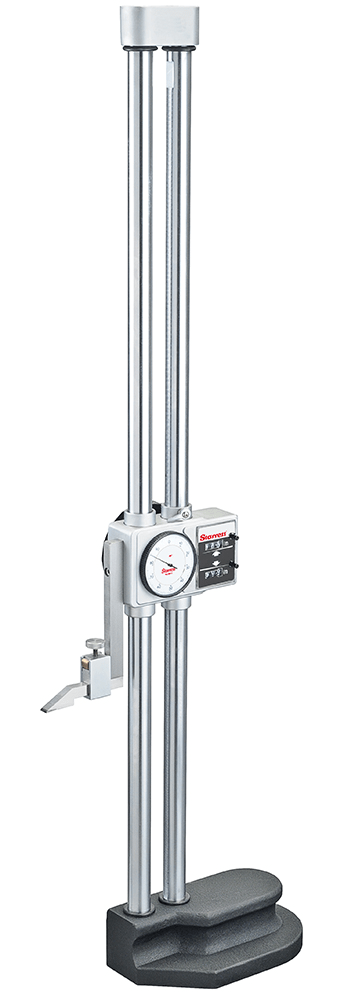

FMM Digital Force Test Stands may be used with L1 software or with a Starrett DFC or DFG digital force gage. They are digital force testers are compact and ideal for high volume, lean manufacturing production. FMM testers are available in three capacities: 110lbf (500N), 330lbf (1500N) and 550lbf (2500N). Two travel lengths are available for all capacities: standard travel at 20" (508mm) and extended travel at 30" (762mm). Crosshead speeds are controlled locally and can be set from 0.002 to 40 inch/min (0.05 to 1016mm/min). A highresolution OLED display shows distance measurements with accuracy better than 20μm (0.0008 inch). Travel limits help prevent load sensor overloading. The FMM force tester can also be controlled using a DFC digital force gage. The DFC force gage serves as a universal controller where it is used to setup the force tester's distance limits, crosshead direction and crosshead velocity for a test. Call 1-800-362-0364 or email: sales@ocscal.com for pricing, demo, or more information.

|

Download Sell Sheet for full details and specs |